Zinc oxide as indium free transparent conducting oxide for silicon heterojunction solar

cells

G. Christmann

1

, D. Sacchetto

1

, L. Sansonnens

1

, G. Wahli

2

, L. Barraud

1

, A. Descoeudres

1

, B. Paviet-

Salomon, N. Badel

1

, B. Strahm

2

, M. Despeisse

1

, S. Nicolay

1

, and C. Ballif

1,3

1

Centre Suisse d’Électronique et de Microtechnique (CSEM), PV-center, Rue Jaquet-Droz 1, CH-

2002 Neuchâtel, Switzerland,E-mail :

2

Meyer Burger Research, Innoparc Rouges Terres 61, CH-2068 Hauterive, Switzerland

3

École Polytechnique Fédérale de Lausanne (EPFL), Institute of Microengineering (IMT),

Photovoltaics and Thin Film Electronics Laboratory, Rue de la Maladière 71b, CH-2000 Neuchâtel,

Switzerland

Transparent conducting oxides (TCOs) with a high conductivity and low optical absorption

are a key requirement for several applications, and in particular for silicon heterojunction

(SHJ) transparent electrical contacts. Currently, indium tin oxide (ITO) is the industry TCO

reference material thanks to its good properties. However, due to the scarcity and high cost of

indium and the large area required for photovoltaic applications, it is highly desirable to find

alternatives relying on low-cost and more abundant materials. Several alternative materials

have been explored to replace ITO, and among them aluminum doped zinc oxide (AZO)

appears as a good candidate [1]. It exhibits indeed a high bandgap (E

g

= 3.3 eV) ensuring

good near IR, visible, near UV transparency, a reasonably high mobility (>10 cm

2

/(V.s) in

100 nm thin films) and the possibility to be doped up to high carrier concentrations (10

20

‒

10

21

cm

-3

), ensuring good electrical conductivity.

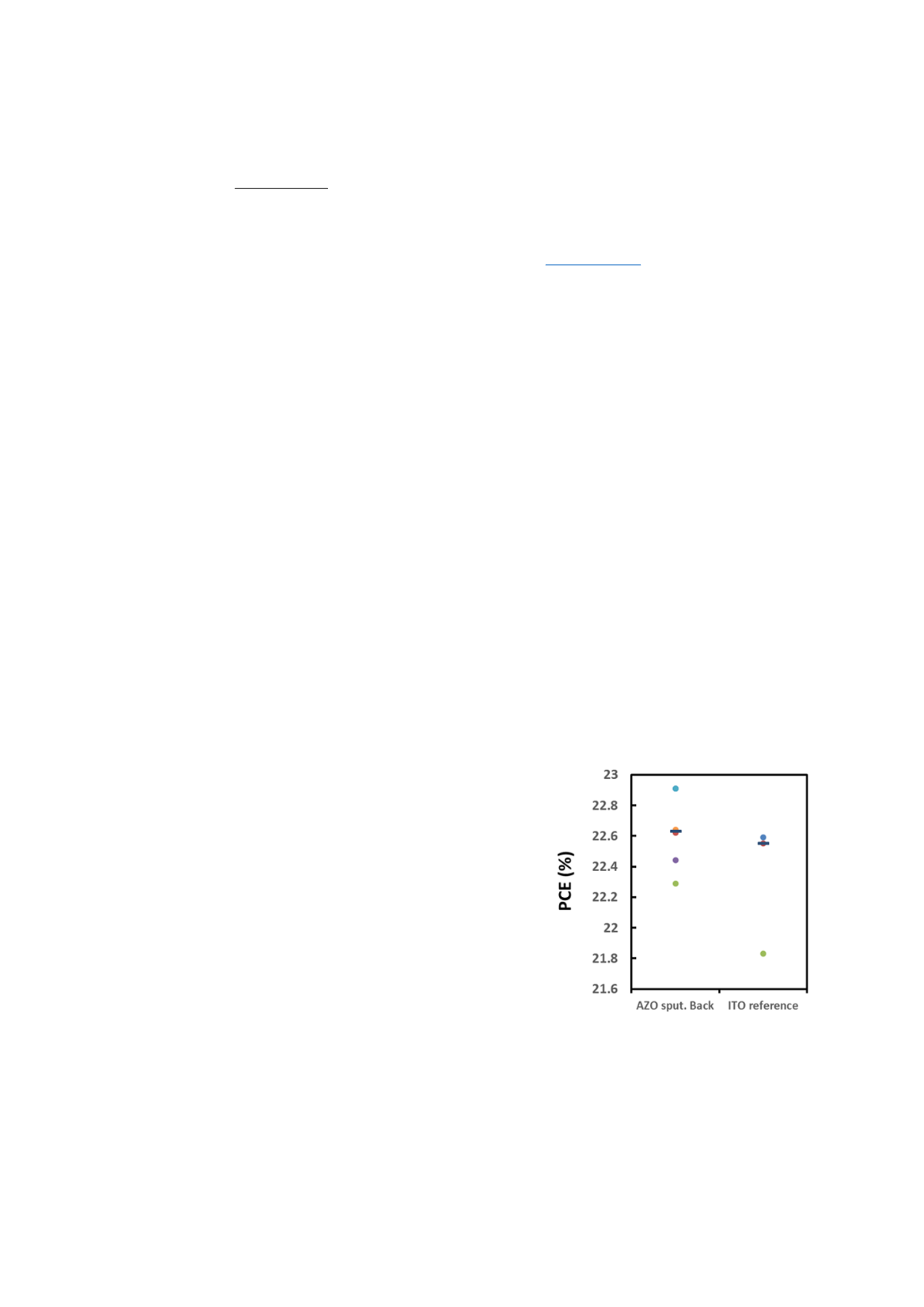

We report here on the use of AZO deposited by sputtering to replace ITO as front and back

contact in SHJ solar cells. Front emitter 2×2 cm

2

test SHJ solar cells were fabricated on 4

inch

n

-type silicon wafers: thin (~10 nm) intrinsic a-Si:H(i) films were deposited by plasma

enhanced chemical vapor deposition on both sides of the wafer for surface passivation. A thin

n-doped a-Si:H film was then deposited to form the back surface field, after that a p-doped a-

Si:H layer was used on the wafer front side to form the hole collector. The transparent

contacts were subsequently deposited by sputtering on

both sides of the cell. AZO was then used either for

front or back contact and compared to reference ITO

material. The cells were finished by sputtering of silver

at the back and screen printing of silver at the front.

When used as back contact (on

n

-type a-Si:H), AZO

leads to solar cells with efficiencies as good if better

than reference cells (see figure 1). However when used

as a front contact (on

p

-type a-Si:H) AZO leads to

significantly reduced efficiencies. The cells are

characterized by a much lower fill factor than for ITO

ones revealing a poor electrical contact. Strategies for

enhancing this contact and bringing it on par with an

ITO-based one will be presented and the results will be

discussed. Transfer of the results to industrial scale tools will also be presented.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme

under grant agreement No 641864.

[1] K. Ellmer, J. Phys. D: Appl. Phys.

34

3097 (2001)

Figure 1: Peak conversion efficiencies of

SHJ solar cells with AZO back contact

compared to ITO reference

O 42

-104-